- Your location > Home > Raspers > Synth

Shredders& Granulators

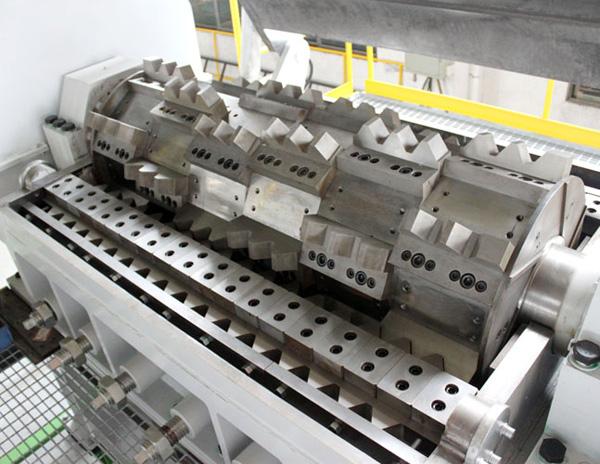

Synth Series Raspers

Synth Raspers are advanced, heavy duty size reducers combining the benefits of both granulators and single shaft shredders in one unit. These machines operate at medium speed with high torque. This in turn results in minimum levels of fines and also uniform product size. The machines are suitable for plastics processing and more commonly rubber products where there is metal contamination i.e. tyres. We offer two different rotor configurations to suit the various applications. The serrated edged blade is an aggressive cut which is well suited to secondary processing of tyres to liberate tire steel. The more conventional straight edge blade is ideal for crumbing of rubber, cable granulation and secondary processing of pre-shredded E-waste/WEEE i.e. circuit boards etc.

The Raspers are applied in a wide range of applications worldwide, below is a list of typical applications:

· Pre-shredded tires – Car Tires, Truck Tires and OTR tires

· Electronic Scrap – Circuit Boards, Cell Phones, Automotive Radiators, Aluminium Profiles etc

· Plastics with Metal Contamination – Copper Cables with Insulation, Reinforced Pipes & Hoses

Standard Features

· Strong welded construction from heavy gauge steel plate

· Maintenance friendly split cutting chamber design

· Rotor & Fixed Blades can be reversed and adjusted so can be used on several edges before replacement.

· Oversized, outboard spherical rotor bearings – prevents bearing damage due to product migration

· Precision machined rotors

· Manual, electric and hydraulic chamber opening mechanisms - quick access to the cutting chamber for maintenance.

· Replaceable wear plates within the cutting chamber.

· Stand Alone Electrical Control Panel - using quality Schneider (Telemecanique) components and Siemens PLC's

· Tested, Approved and Certified to the applicable CE safety standards