- Your location > Home > Plastic washing plants > PP Woven Bags

Recycling Plants

PP Woven Bags Washing Plants

Our PP Woven Bag Washing Plants are high throughput, high performance recycling systems designed especially this application. Through extensive research of the characteristics of PP woven bags, we are able to provide specific proposals to which will reduce the quantities of fines created, therefore material loss is kept to a minimum. In addition, our R&D team have developed an advanced drying solution for PP woven bag material which forms a key part of our recycling system.

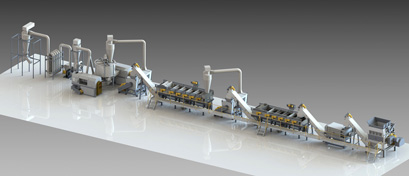

• Shredder – wet shredding for size reduction and washing

• Screw Washer 1 – washing and material transportation

• Pre-washer – removal of some sands and other dirt

• Screw Washer 2 – washing and material transportation

• Sink-Float Separation Tank 1 – removal of some contamination and helps wash the material

• Horizontal Friction Washer 1 – high speed washing/scrubbing of material

• Sink-Float Separation Tank 2 – removal of some contamination and helps wash the material

• Horizontal Friction Washer 2 – high speed washing/scrubbing of material

• Screw Press with advanced feeding system – mechanical de-watering through squeezing action

• Thermal Drying System – hot air drying of the product

• Big-Bag Station

• Control panel

The correct combination and sizing of the above listed equipment will provide a reliable, efficient PP woven bag recycling system that will produce a high quality product ideal for sale, or for converting in pelletizing equipment.

• Shredder – wet shredding for size reduction and washing

• Screw Washer 1 – washing and material transportation

• Pre-washer – removal of some sands and other dirt

• Screw Washer 2 – washing and material transportation

• Sink-Float Separation Tank 1 – removal of some contamination and helps wash the material

• Horizontal Friction Washer 1 – high speed washing/scrubbing of material

• Sink-Float Separation Tank 2 – removal of some contamination and helps wash the material

• Horizontal Friction Washer 2 – high speed washing/scrubbing of material

• Screw Press with advanced feeding system – mechanical de-watering through squeezing action

• Thermal Drying System – hot air drying of the product

• Big-Bag Station

• Control panel

A typical PP woven bag washing plant would be configured as shown below.

The correct combination and sizing of the above listed equipment will provide a reliable, efficient PP woven bag recycling system that will produce a high quality product ideal for sale, or for converting in pelletizing equipment.