- Your location > Home > Plastic washing plants > HDPE bottles

Recycling Plants

HDPE Bottles Washing Plants

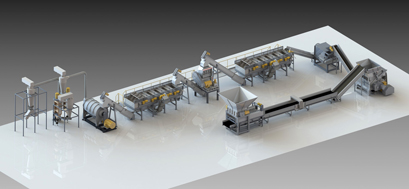

Our HDPE Bottle Washing Plants are designed for recycling of post consumer HDPE bottles including labels. These systems produce uniform size HDPE flakes with high purity and low moisture level. Due to the variety of product standards and differing condition of HDPE bottles being recycled in different regions we offer a range of systems that can be tailored to suit your individual requirements. A typical HDPE bottle recycling system would include the following components:

• Disc classifier – removes stones, heavies and loose caps

• Sorting Belt (Optional) – manual sorting of bottles by type and colour

• Metal detector – detecting metal contamination that may remain in the bottles

• Shredder with Force Feeding Device – pre-shredding of bottles

• Pre-washer – removes some of the contamination i.e remnant liquids

• Sink-Float Separation Tank 1 – pre-washes the material and protects the knives of the granulator

• Granulator – wet grinding for size reduction and washing

• Screw Washer – washing and transportation of material

• Sink-Float Separation Tank 2 – washes the flakes and removes contamination

• Centrifugal Dryer – mechanical dewatering of the flakes

• Zig-Zag Classifier – separation of the remaining labels and fines Big-bag station

• Control Panel

• Disc classifier – removes stones, heavies and loose caps

• Sorting Belt (Optional) – manual sorting of bottles by type and colour

• Metal detector – detecting metal contamination that may remain in the bottles

• Shredder with Force Feeding Device – pre-shredding of bottles

• Pre-washer – removes some of the contamination i.e remnant liquids

• Sink-Float Separation Tank 1 – pre-washes the material and protects the knives of the granulator

• Granulator – wet grinding for size reduction and washing

• Screw Washer – washing and transportation of material

• Sink-Float Separation Tank 2 – washes the flakes and removes contamination

• Centrifugal Dryer – mechanical dewatering of the flakes

• Zig-Zag Classifier – separation of the remaining labels and fines Big-bag station

• Control Panel

The correct combination and sizing of the above listed equipment will provide a reliable, efficient HDPE bottles recycling system that will produce a high quality product ideal for sale, or for use in pelletizing equipment.

Testing

Prior to delivery from our facility, all plastic washing plants are set up and tested under "real world" conditions to ensure the plant capacity and quality of the finished product are guaranteed. Customers are welcomed and encouraged to attend these trials to see their plant in operation, receive training on the operation and maintenance of their system, and to see similar equipment in build.